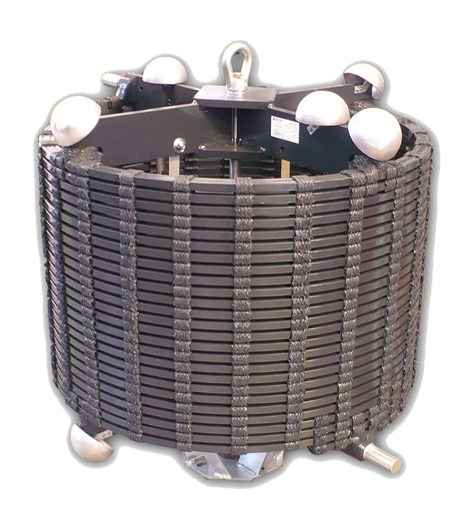

Line traps for powerline communications

The Line Trap is a high performances PowerLine Carrier system, compliant with the latest IEC 353 recommendations, offers a wide range of inductances, hence multiple current and voltage values to be used in modern power systems having to cope with higher nominal and short circuit power levels with subsequent very severe mechanical forces in the main coil of the traps. PLC (PowerLine Carrier) systems are employed by utility companies in many countries as a main component of the communications systems. They are used to transmit different signals and for the usually required transmission functions, such as telephony, fax transmission, remote control, telegraphy, teleprotection and data.

Line Traps role consist in limiting PLC's signals to particular sections of the power lines and prevent their transmission towards unwanted directions, enabling therefore the re-use of frequency bands in a power network. Since the Line Trap is installed in series and connected with the power line, it must be designed to withstand the maximum continuous current as well as any short circuit current on the line. In order to do not disturb the power transmission, the Line Trap impedance has to be negligible at the power frequency, but it must be relatively high over the frequency band appropriate to carrier transmission. Therefore Line Traps allow maintaining defined attenuation and impedance properties of a PLC link in all operating conditions of the involved power network including the grounding of the power line at both ends. Main benefits of the Line Trap are loss reduction, high mechanical strength, high short-circuit withstand capability, excellent cooling and light weight.