High security and performance unit.

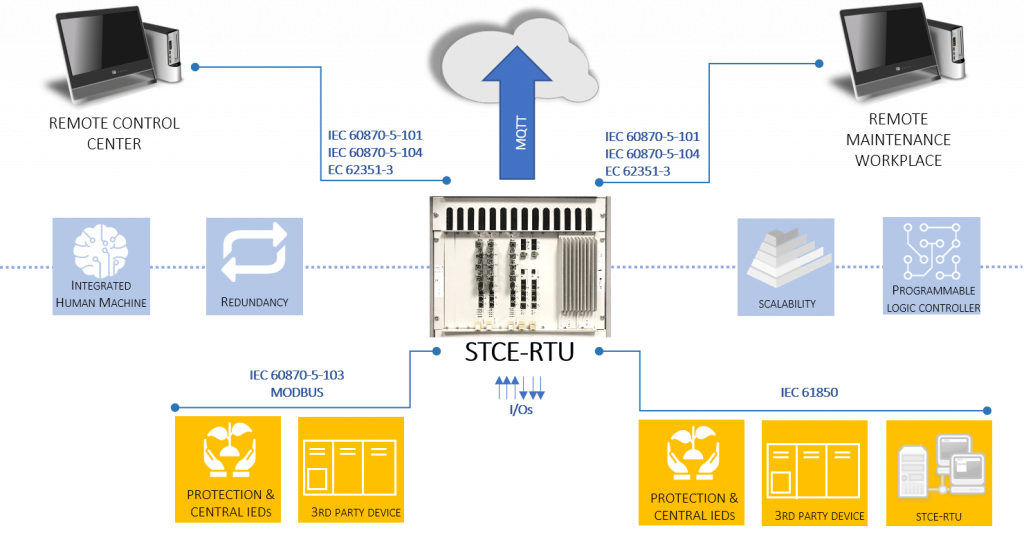

Efficient management of electrical networks requires that the remote control peripheral equipment manage information from and to the controlled plant in an integrated way with the other plant devices, communicate with management centers in a quick and secure manner, and ensure high level of security in configuration, maintenance and access to recorded data.

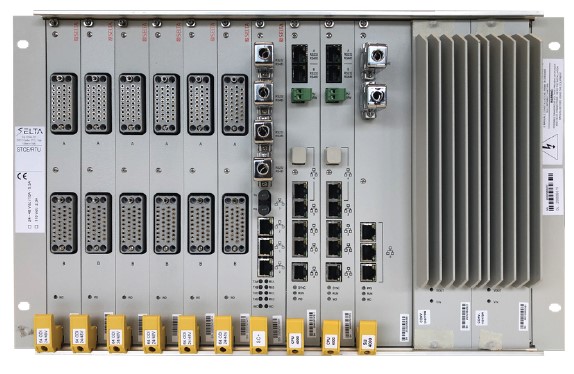

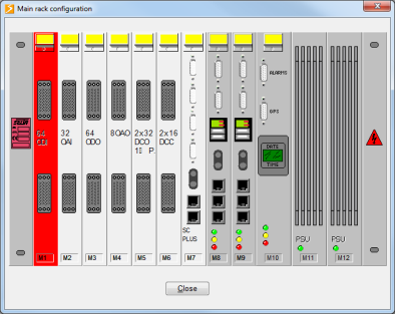

STCE-RTU 4k, like all remote contriol units belonging to STCE-RTU series, guarantee high processing and communication capacity, modular architecture with distributed intelligence for an optimized deployment, high capability in chronological discrimination and synchronization with high precision clocks, advanced configuration and diagnostic tools for simple, timely, effective and secure maintenance interventions, high levels of security and information protection to reduce the vulnerability and risk of cyber attacks (Cyber Security). STCE-RTU 4k is also used, besides electrical networks, in the control of other types of geographically distributed plants such as gas pipelines, oil pipelines, water treatment and district heating plants in concentrated, distributed and mixed architectures.

MONITORING AND CONTROL: signals, measures and pulses acquisition; commands and set-points; filters, thresholds and scale factors programming; concentration of information coming from local or remote devices; time stamp assignment with 1 ms resolution; automation logics; MQTT Publisher/Subscriber protocol for IoT applications; client-based requirements applications; Terna BDE; power supply, CPU and communication boards redundancy

COMMUNICATIONS: dialogue with multiple control centers and more IP address per center; telecontrol protocols IEC 60870-5-101/104, IEC 61850, IEC 62351-3, MQTT; 4 redundancy group for IEC 60870-5-104 protocol towards the same center; redundancy bonding; multi-protocol gateway mode; proxy mode

SECURITY: security based on HTTPS, Radius, SSH; network management SNMP V.3 with USM authetication; SysLog for the remote control of all security information relating to the device; Security Log for tracing access; Brute Force Attack functionality; NTPv4 authenticated synchronization

CONFIGURATION AND MAINTENANCE: SSH and HTTPS secure access; application for rapid and controlled configuration of communication parameters and plant interfaces; run-time checks for errors and inconsistencies; I/O and communication units interchangeable without the need for configuration; web-based access to default data, field events log, diagnostic, security events and run-time display of I/O status and alarms with configurable display filters; firmware download/upload, device configuration and automation available via web encrypted communication (anti-tampering); to failures. Net recorder funzionality for trafic logging; dedicated memory for recordings; licenses management

LOCAL AUTOMATION: simulation and execution of automation sequences compliant with the IEC 61131-3 standard using the programming languages: IL (Instruction List), LD (Ladder Diagram), FBD (Function Block Diagram), ST ( Structured Text) and CFC (Continuous Function Chart). A software programming simulator allows the testing of implemented logics. STCE-RTU also allows online analysis of the automation operating status, manual shutdown and start of the automation (via software), automatic restart of the automation each time the device is switched on